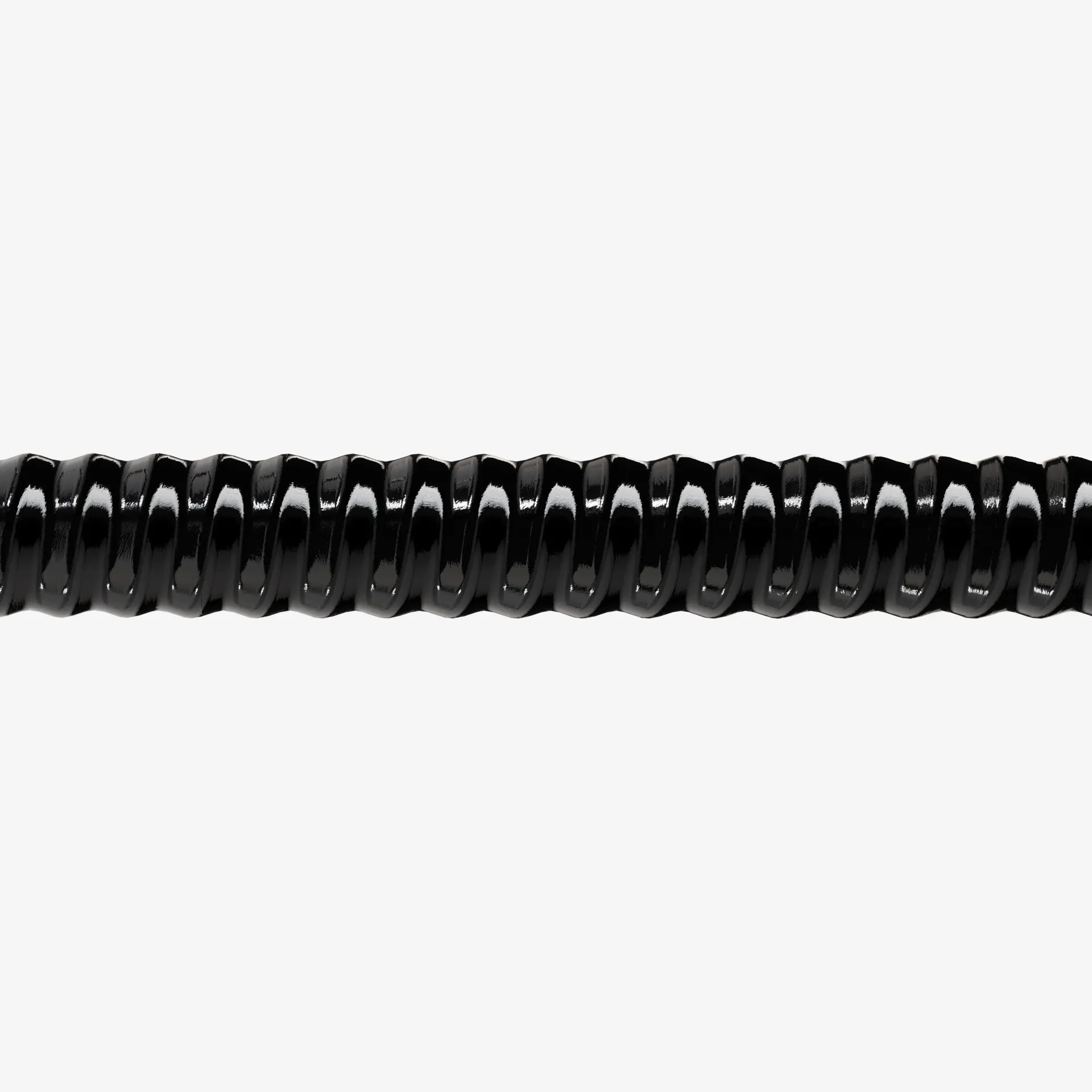

GFRP Bolts

Minova’s glass‑fibre reinforced polymer (GFRP) solid and hollow bolts deliver high tensile strength, corrosion resistance and full cuttability for efficient strata support in mining and tunnelling.

Product Benefits

Sectors

Applications

Product Details

Minova’s glass‑fibre reinforced polymer (GFRP) bolt range combines high strength, low weight and full cuttability to keep your operations productive and your people safe. Available as solid and hollow injection variants, these systems provide immediate, reliable strata support across mining, tunnelling and civil works. Solid GFRP bolts use a continuous all‑thread profile to achieve high ultimate loads and excellent bond with cementitious grouts and fast‑setting Lokset® resin capsules; anti‑static options are available. Hollow GFRP bolts enable controlled, high‑pressure resin or grout injection to consolidate fractured or weathered ground without delaying heading. Typical solid bolt diameters span 18–32 mm with ultimate loads up to 560 kN, while hollow variants around 25 mm outer diameter support demanding injection regimes. Across the range, GFRP’s corrosion resistance suits permanent and temporary support, and its low density—about 30 percent of steel—improves handling and reduces logistics underground.